INTRALOGISTIC SOLUTIONS

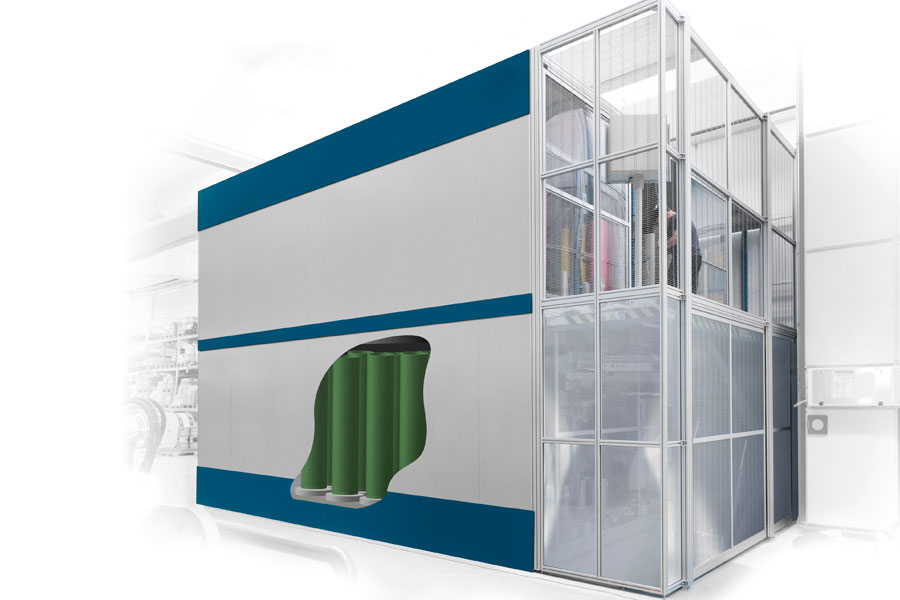

Automatic sleeves storage system

The sleeves in the flexo printing process represent an important asset: the quality of the printed material depends also on the accuracy and quality of the sleeves. Each single print run relies on how the sleeves have been stored and protected when not in use. Often the sleeves are left on the floor in the proximity of the printing machines grouped sometimes in a random way.

The Sleeve Storage is aimed at preserving in the best way the quality of the sleeves and in helping the operators to properly store and use each single sleeve.

The basic principle of the storage is to keep the sleeves in vertical position; this will help to make the sleeves lasting for long time in a good shape.

The second added value of the storage is to help in the operability; a well-organized distribution of the sleeves in various racks certainly helps the operator to search and find in a very short time the required sleeve.

Sometimes a very large set of sleeves, about 900 and up, require a more sophisticated solution:

the Automatic sleeve storage. Two are the main added values, if compared to the Manual solution.

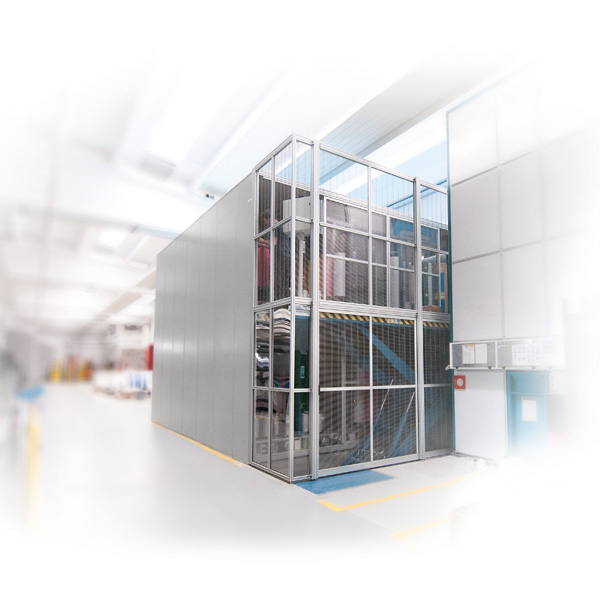

Higher capacity: the storage can be on various levels with an easy access by the operator in order to load and unload the storage. High sleeve density is guaranteed by the fact that the operator is not moving along the racks as in the manual version. Here the operator is getting the sleeves from a “pick-up point”. Circa 900 sleeves are stored in an area of 48 square meters with a height of 5 meters. The modularity is also guaranteed in order to fit any area the user wants to assign to the sleeve storage.

Less manual work for storing and extracting sleeves: with the Automatic storage the operator is communicating with the storage via a simple warehouse management software that allows him to select the type of sleeves on a monitor. The storage searches for the sleeves and extracting them at the “load/pick-up points”. Therefore, the operator doesn’t need to know where the sleeves have been stored, he only has to collect the material as provided by the storage.

Moreover, each sleeve is tracked and easily searchable: statistics on the usage of the single sleeves are available any time for a better usage of the material.

Automatic storage from 900 up to 1300 sleeves have been installed so far.