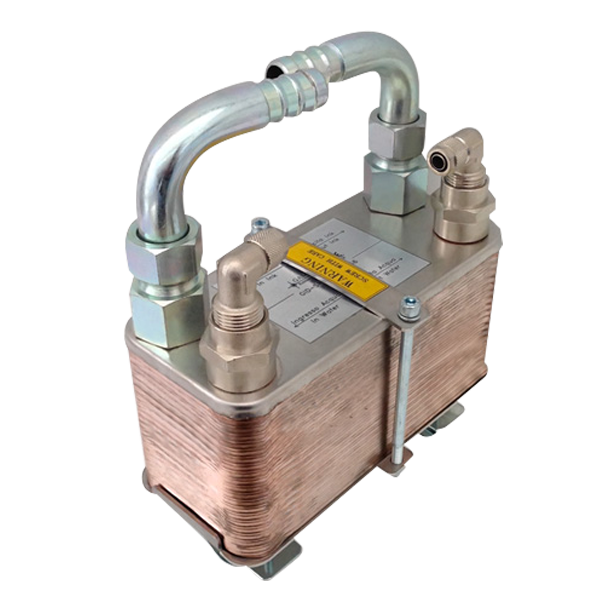

HEAT EXCHANGER

Ink temperature control and correction system G90

The ink temperature system measured by a temperature sensor, which sends the measurement to the electronic control, which operates with reference set by the operator.

Applications

Rotogravure / Flexography / Lamination / Reprint / Varnish / Bi-Components Varnish / Glues

The system of control and correction of the ink temperature G90, is composed of plate heat exchangers or tube, one per color, pneumatic valves and management software.

A temperature sensor, which can be integrated in the detector viscosity, measure the ink temperature.

The G90 automatic system, according to the temperature value determined previously by the operator during the calibration, regulates the coolant flow within the heat exchanger to obtain a heat exchange and therefore a stable ink temperature during the printing phase.

In the printing process, the increase of the ink temperature than that of the printing process is also influenced by the environment where the printing machine is installed.