VISCOSITY CONTROL AND CORRECTION – VISCOMETERS

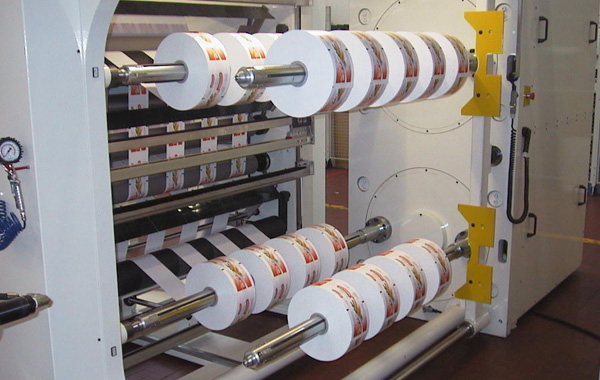

G1000 IQS – Automatic Ink Quality System

The G1000 has been developed to keep ink quality stable during the printing process and to reduce solvent and ink consuption. It is not a simple viscometer, but is a completely automatic system, equipped with viscosity and temperature control, magnetic filter and sophisticated production controls and customized for each rotogravure machine.

This new system features several advantages: the viscosity and temperature control of ink reduces the level of ink and solvent, and it allows for quicker start-ups and waste reduction. Furthermore, it reduces ink blade lines, thanks to the magnetic filter wich attracts steel filings. All those features help make the printing process more productive and efficient.

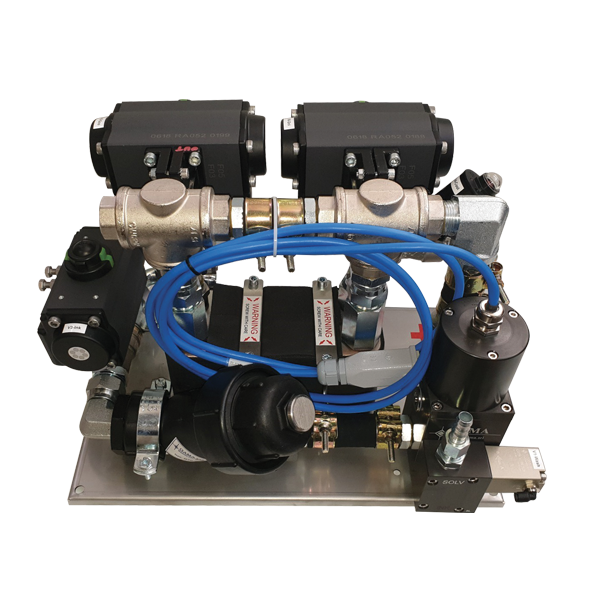

VISCOMETER FOR SOLVENT AND WATER BASED INK

MAGNETIC FILTER

HEAT EXCHANGER UNIT

OPTION pH CONTROL