VISCOSITY CONTROL AND CORRECTION – VISCOMETERS

Viscometer G29

The G29 is a microprocessor controller for the regulation of the viscosity of water based ink. The viscosity measurement is made through a vibration sensor, inline with the ink piping without moving parts.

This sensor emits a frequency to the controller that processes the viscosity in seconds (cup ZAHN, FORD etc.) and, then to the solvent valve, which maintains the value according to the reference signal.

The cleaning of the viscometer is made at job end, while washing up.

Applications

Rotogravure and Flexographic presses. Water and solvent base ink.

Console and command panel

PC with 15 ” touchscreen. All colours displayed on the screen. All viscosities are displayed on a graphic bar. Individual cup settings to desired reference. Save up to 10.000 different jobs. Temperature control function displayed. Error signals (no ink, no water or viscosity over tolerance).

Control G29

Rack system cabled by connectors. Installed in a cabinet. Serial communication between PC and control.

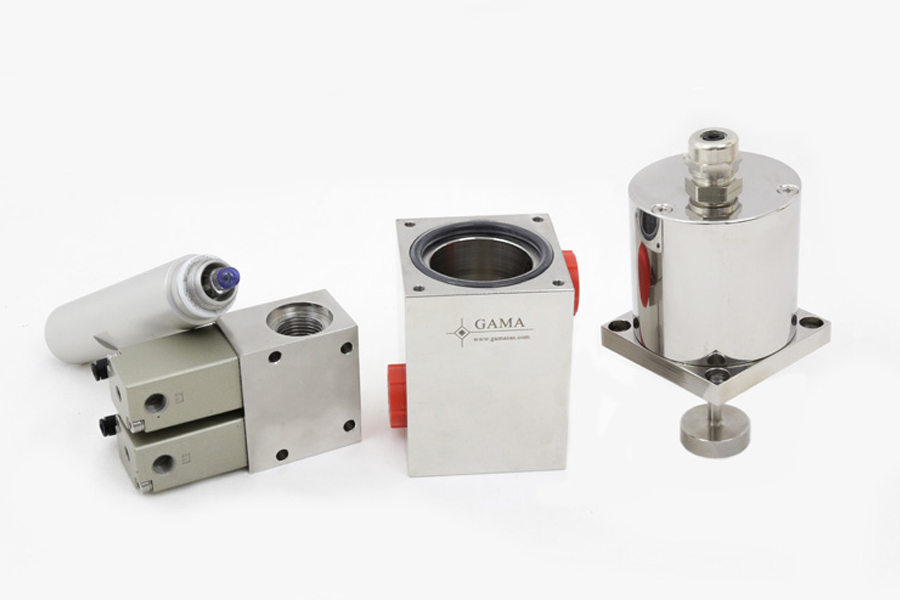

Viscometer G29

G29-RIV stainless steel to install in a danger zone near the ink tank. Water correction through pneumatic valve. Feeding by rotary or alternative pumps. Viscosity is measured with 1% accuracy.

Option

HMI 4,3” – 9,7” touchscreen display. Control pH G80 by a probe dedicated. Control of temperature by G90 heat exchanger.

Maintenance and cleaning

At the end of the job, the cleaning of sensors is made simultaneously with the press ink cleaning system. No mechanical parts or moving components.

This documentation is not contractual information. Specifications are subject to modification without notice.